Technical Ceramics

Aerospace

Since the 1960s Morgan Technical Ceramics has been making precision-engineered materials, components and assemblies to meet the exacting needs of the Aerospace Industry. From instrumentation and control systems to engine monitoring, guidance systems and satellite positioning equipment, our superior materials technology and impressive manufacturing capability have delivered real performance benefits to leading names in the global Aerospace Industry.

Get a quoteAerospace Products

We produce ceramic components, braze alloys, and brazed ceramic-to-metal assemblies to tight specifications. Our manufacturing is fully integrated, using Morgan manufactured ceramic grades, metallising inks and braze alloys, and we are flexible to the full volume range a customer may require.

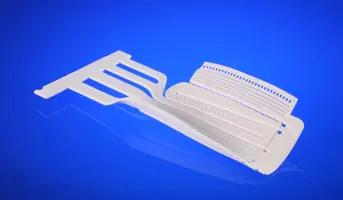

Aerospace Electrical Components

Electronic packages

Terminal blocks

Need more information? Start talking to us today

Aerospace Material Properties

The key properties for Aerospace materials include:

- High temperature resistance and stability during thermal fluctuations

- Electrical insulation

- Resistance to corrosion

- Wear resistance

- Chemical stability

- Low out-gassing

- Mechanical strength

Aerospace Products Capabilities

Our combined expertise in metallisation, braze alloy, and ceramic development; production and brazing; and our internal testing/analysis assets such as thermal cyclic testing provide the required skills and facilities our customers need to the performance of their aerospace platforms.

Aerospace Ceramics Questions

How are ceramics used in aerospace?

Ceramics are used as components within aerospace applications such as temperature sensors, electrical connectors or feedthroughs, and as protective sheathes for thermocouples due to their high thermal and electrical resistance. Ceramics are also used as a consumable form during the investment casting of turbine hardware (such as stationary vanes) to form internal cooling channels within the hardware.

Why are ceramics used in aerospace?

Ceramic materials are lightweight compared to metals, they have high temperature resistance and stability with thermal fluctuations. Ceramics are resistance to corrosion and chemical degradation and have electrical insulation properties.

What ceramics are used in jet engines?

Aluminosilicates are often used for ceramic cores to manufacture the investment castings to balance the ability to easily and fully remove the core material after casting versus the need for a tight-tolerance, rigid core with sufficient strength during the casting process. Aluminas are often used within sensors, connectors, and feedthroughs due to their high thermal resistance, thermal-shock resistance and electrical insulative properties.

How are ceramics used during the manufacture of jet engine turbine blades?

Ceramic cores are used during the investment casting process that produces turbine blades. These cores form the internal cooling channels of the turbine blades during the casting process. After the cast blade cools, the core is removed by dissolving the core, leaving the remaining empty internal cooling cavity within the blade. Ceramic is ideal for this application because it can withstand the temperatures of the metal casting process achieving the tolerances needed within the metal blade and can be easily removed (dissolved) post casting without damaging the cast blade.