Technical Ceramics

Maximum Use Temperature

Contact usMaterials are often grouped by their relative service temperature range. Soda glass and borosilicate glass are generally used below 500°C, Silicon is used below 600°C, and glass ceramics and glazed porcelain are used below 1000°C. The maximum use temperature of technical or specialty ceramics (e.g. unglazed porcelain, fused silica, alumina, zirconia, silicon carbide, magnesia, boron nitride) is typically between 1000°C and 2000°C, exceeding many metallic alloys and all polymers. Ceramics that operate above 2000°C are often referred to as ultra-high temperature ceramics (UHTC). These UHTC often include carbides and borides and, because of their extreme thermal stability, are frequently considered for supersonic and hypersonic applications.

|

|

Typical maximum use temperature (°C) in inert atmosphere |

| Recrystallized SiC | 2000 |

| SSiC | 2000 |

| Calcia Fully Stabilised Zirconia | 2000 |

| Alumina | 1400-1800 |

| Magnesium Aluminate | 1700 |

| Porous Alumina | 500-1700 |

| Porous Aluminium Silicate | 1350-1650 |

| CVD SiC | 1600 |

| Nitride Bonded SiC | 1450 |

| Aluminium Silicate | 1400 |

| ZTA | 1400 |

| SiSiC | 1350 |

| Mullite Bonded SiC | 1300 |

| Silicon Nitride | 1200 |

| Fused Silica | 1000 |

| Glass Ceramic | 1000 |

| Porous Fused Silica | 850 |

| Partially Stabilised Zirconia | 500 |

Compressive Load

From a practical perspective, the maximum use temperature of any ceramic only has meaning in the context of its intended use. For example, a ceramic part under a compressive load will have a lower maximum use temperature compared to the same ceramic part that is not subjected to a compressive load. Likewise, examples of other considerations include how a material’s electrical properties vary with temperature, whether thermal shock resistance is a need, and what type of atmosphere (e.g. vacuum, inert gas, oxygen) will exist.

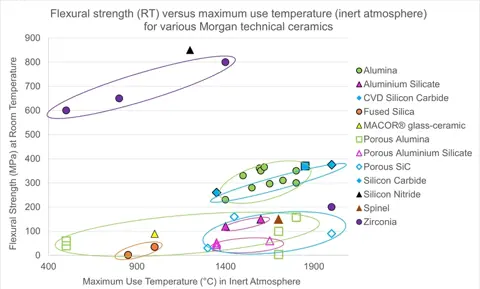

Illustrating this point, ceramics’ maximum use temperatures are often plotted relative to another property attribute to better illustrate the ceramic’s relative position versus alternate materials.

Note: At elevated temperatures, flexural strengths can be lower than room temperature values.