Technical Ceramics

Dielectric Constant

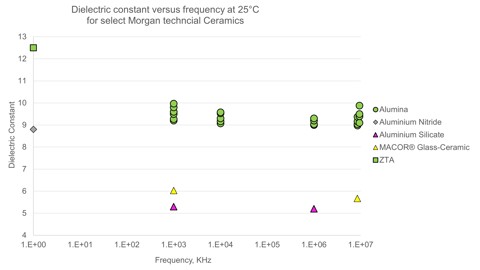

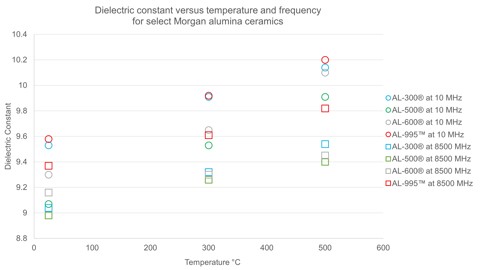

A material’s dielectric constant (K) (also known as relative permittivity) is the ratio of a material’s permittivity relative to the permittivity of a vacuum. Permittivity is a measure of how much a material polarises in response to an applied electric field, resulting in stored energy in the material.

Contact usA vacuum has the lowest permittivity possible, meaning it absorbs the least amount of energy from an electric field. The relative permittivity of a vacuum to itself is 1, the lowest dielectric constant possible. Therefore, a material with a very high permittivity will have a very high dielectric constant. A material with a dielectric constant of 10 will absorb 10x more electrical charge than a vacuum.

Permittivity changes with temperature and as the electric field frequency changes, so indicating the frequency and temperature at which the permittivity measurement was made is necessary.

Electrical Insulator

An electrical insulator should have high resistivity, high dielectric strength, low dielectric loss, and a low dielectric constant at the application’s electrical frequency and temperature range. Other considerations will narrow the material candidates such as mechanical properties (thermal expansion, mechanical strength), chemical resistance (resistance and dimensional stability when exposed to oils, water, and other fluids/chemicals/weather/radiation/plasma), thermal properties and non-flammability, purity, and the ability to form and assemble the desired shape or device.

High Purity Alumina

Typically, High-purity (>97%) alumina (aluminium oxide, Al2O3) is used for high-voltage insulators, although aluminium nitride is also used due to its ability to quickly dissipate heat, and machinable glass-ceramics such as MACOR® is specified particularly for low-unit volume applications.

Porous Aluminium Silicates

Besides being insulative, porous aluminium silicates demonstrate some of the best thermal shock resistance, even versus dense alumina and dense aluminium silicates, although these properties depend on size and shape of the part. This shock resistance makes these silicates particularly useful for thermocouple sheathes.