Technical Ceramics

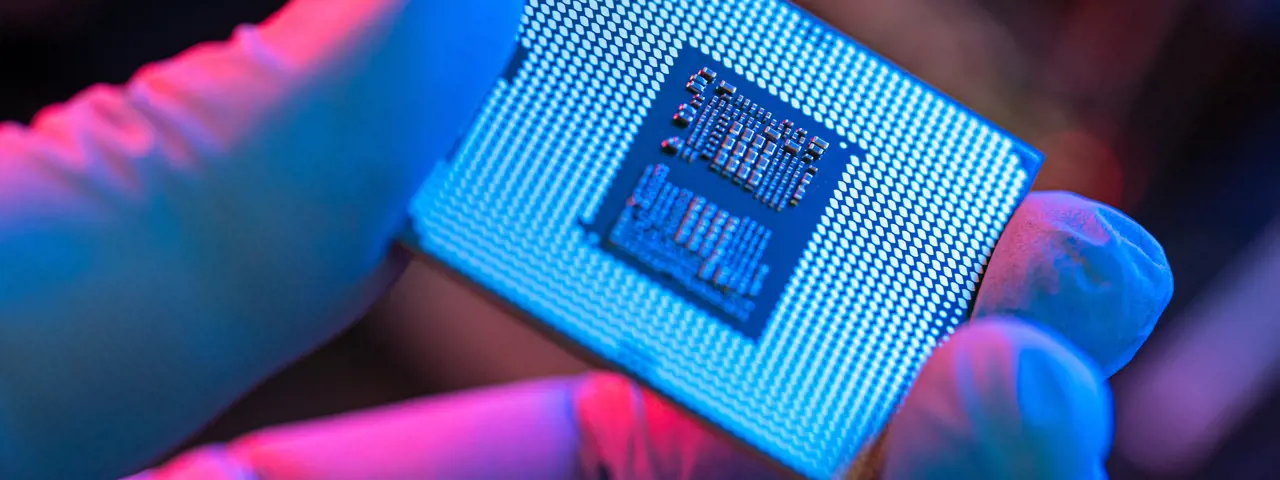

Semiconductor Processing

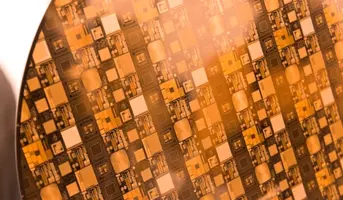

Morgan Technical Ceramics is a global market leader and specialises in supplying materials and components for manufacturing processes of semiconductors and other high quality demanding markets such as LED displays for more than 20 years.

Get a quoteSemiconductor Applications

Morgan products are used in fabrication plants all over the world and helping semiconductor manufacturers to optimise their processes, increase production yield and help to reduce their total cost of ownership.

Our semiconductor components are used in applications including:

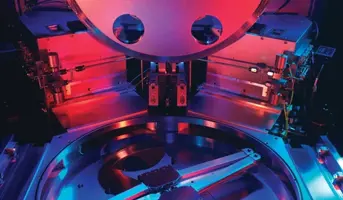

Deposition

Chamber liners

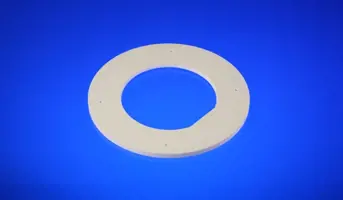

Edge rings

Gas mixing manifolds

Isolator and shield rings

Lift pads and pins

Plasma tubes

Dry Etch

Electrostatic chuck top layers

Focus ring

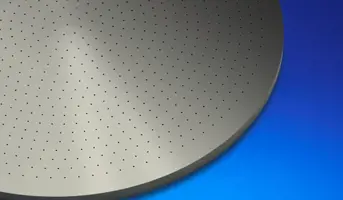

Showerheads, gas distribution plates

Ion-implant

Shield rings

Lithography

Lamp covers

Plasma tubes and light-source components

Thermal heat sinks

Wafer chucks

MOCVD

Chamber components (e.g. wafer carriers, wafer susceptors)

SiC Single-Crystal Boule Growth

High purity SiC source material

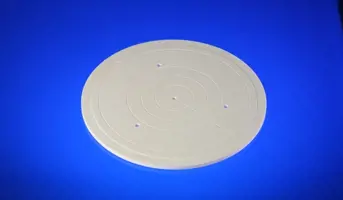

Wafer Handling

Charge dissipative end effectors

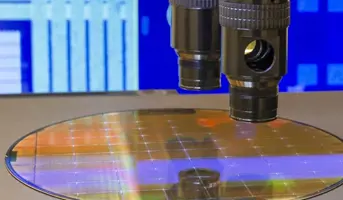

Wafer Inspection

Electrical insulator assemblies

Need more information? Start talking to us today

Semiconductor Products

We offer a wide range of products for the Semiconductor Process Equipment (SPE) industry including:

- High-purity alumina chamber and lithography components

- High-purity alumina targets

- CVD SiC chamber and lithography components

- CVD SiC targets

- CVD SiC source material for growing single-crystal boules or ingots

- High-purity alumina, ultra-high surface roughness coating

Semiconductor Materials

Our materials offer:

- Plasma resistance

- Low-particle shedding

- High purity

- High temperature dielectric performance

- High Weibuell modulus aluminas

Semiconductor Processing Ceramics Questions

How is ceramic used in semiconductor processing equipment?

Ceramic components provide a clean surface, dimensional stability and resistance to degradation in semiconductor processing equipment such as chamber linings and rings.

Why are ceramics used in semiconductor processing equipment?

Morgan CVD SiC ceramic material has a unique combination of excellent thermal, electrical and chemical properties that makes it well-suited to applications across semiconductor industries where a high-performance material is required.

What are the advantages of Morgan semiconductor products?

- Ultra-pure 99.999% (by GDMS)

- Outstanding corrosion resistance in plasma applications

- Proven durability in high temperature ammonia environments

- Excellent thermal shock resistant

- High thermal conductivity

- Excellent stiffness to weight ratio

- Fine grained microstructure

- Non-porous

- Two resistivity grades

- HR Grade: >10 Ω-cm

- ELR Grade: <0.1 Ω-cm