Technical Ceramics

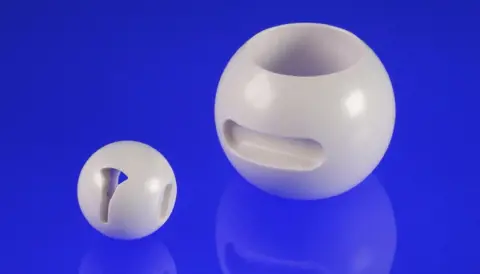

Ceramic Hard Wearing Valve Trim

We use our tough, high strength range of ceramic materials, including Nilcra® Zirconia (PSZ or Magnesia Partially Stabilised Zirconia), Silicon Nitride (Si3N4) and SSN to make high performance valve trim for corrosive and abrasive fluids in demanding severe service environments.

Advantages of Nilcra® Zirconia Ceramics

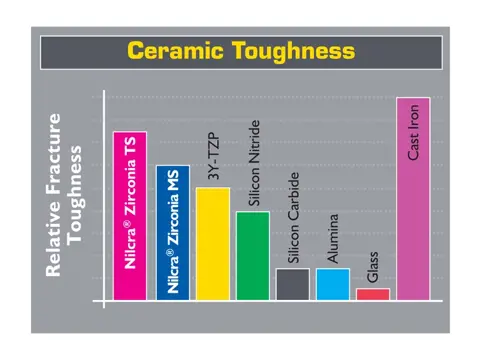

- High impact strength – tougher than Tungsten Carbide

- High mechanical strength

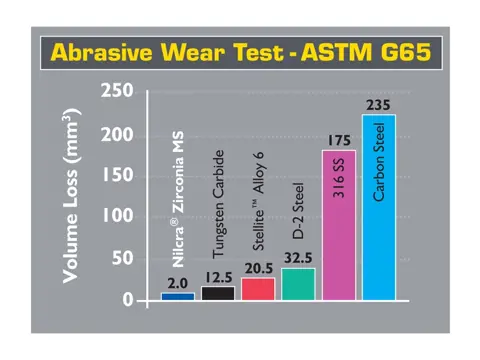

- Outstanding wear resistant compared to conventional or high chrome metals

- Corrosion resistant to most acids and bases

- Excellent resistance to cavitation and flashing

- High hardness

Find out more about our ceramic grades:

Our hard wearing, corrosion resistant ceramic materials are ideally suited for valve trim is used in:

- Ceramic ball valves

- Ceramic butterfly valves

- Ceramic globe valves

- Ceramic sliding gate valves

- Ceramic rotary valves

- Ceramic linear control valves.